Background to the Fuel Transiton in the Egyptan Cement Sector

For a long time, Egypt's cement industry has mainly relied on natural gas and a small amount of heavy crude oil as energy sources. But since 2012, Egypt has encountered a severe energy crisis, and the daily production of natural gas has dropped from 166 million cubic meters to 133 million cubic meters. Affected by the natural gas crisis, many cement plants stopped production or imported cement clinker. At the same time as the natural gas shortage, power outages are commonplace in Egypt. In the case of the energy crisis, the energy choice of Egypt's cement industry began to turn to coal and petroleum coke.

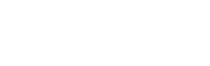

In switching to coal, the government has introduced a series of regulatory measures, laws, and regulations to ensure that the transition will not bring air pollution and additional greenhouse gas emissions. Coal combustion will produce particulate matter, and regulations require that sprinkler systems, dust removal systems, and windbreak belts be used during production to reduce particulate matter emissions. At the same time, the government has formulated strict regulations to control the pollutants in the flue gas. Through the coordinated flue gas treatment method, the concentration of total particulate matter has dropped by more than 50%, and the nitrogen oxides have also reached the corresponding standards. At the same time, the government has also made requirements on greenhouse gases: the additional greenhouse gas emissions (about a 30% increase) caused by the switch from natural gas to coal must be directly offset by other means.

How Pollutants and Greenhouse Gases Are Produced in the Cement Industry

After the cement industry turned to coal energy, the monitored pollutants included sulfur dioxide, nitrogen oxides, particulate matter, heavy metals, carbon dioxide, and soot.

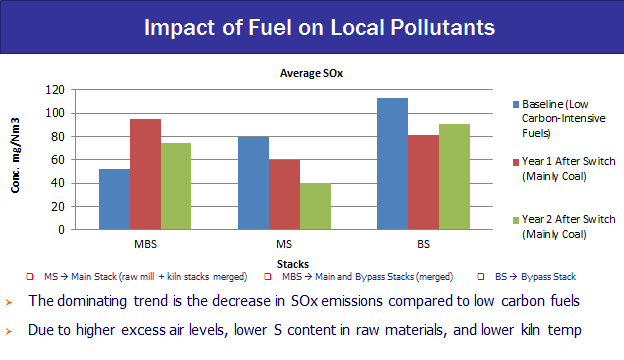

The main sources of nitrogen oxides are the oxidation process of nitrogen-containing compounds in fuels and the thermal nitrogen fixation effect in high-temperature combustion gases. When the amount of combustion increases, the emission of nitrogen oxides increases. From natural gas to coal, the content of nitrogen increases, which is why nitrogen oxides will increase. However, with coal, the temperature drops, and so do the emissions of nitrogen oxides.

Carbon monoxide is mainly caused by incomplete combustion. Incomplete combustion is sometimes because the combustion temperature is not high enough, the residence time in the combustion zone is not long enough, or the mixture of fuel and oxygen is not sufficient, that is to say, when the content of the combustible is higher than that of oxygen, it cannot be fully combusted.

There are two main sources of carbon dioxide: the carbon dioxide produced by fuel combustion and the carbon dioxide produced by using raw materials such as lime in the production process.

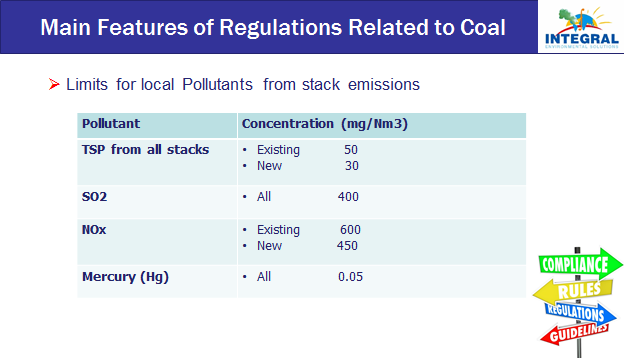

Impact on emissions after fuel switching

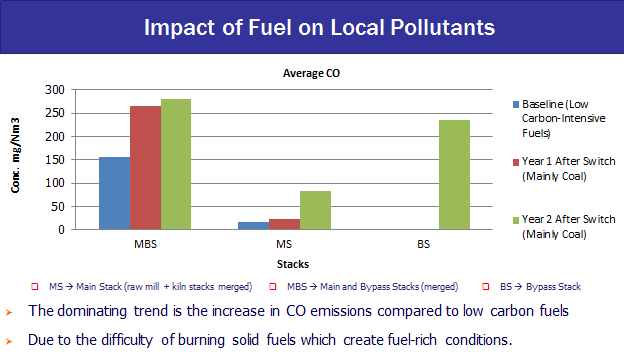

In the graphs below, the baseline in blue is the low-carbon-intensity fuel, the red represents the first year after switching to coal, and the green represents the second year after the switch. Monitoring found that after the conversion, sulfide emission decreased, nitrogen oxides, carbon monoxide, and mercury increased, and the emission of total suspended particulate matter did not change significantly.

Osama Abdel-Aziz wrote policy papers for Egypt on carbon pricing and carbon response measures and preparations for the entry into force of the Paris Agreement. A knowledge product titled "Baseline and Mitigation Compendium" was prepared for UMFCCC, aimed at assisting countries in developing baseline and mitigation scenarios for nationally appropriate mitigation actions or mitigation actions in any sector.